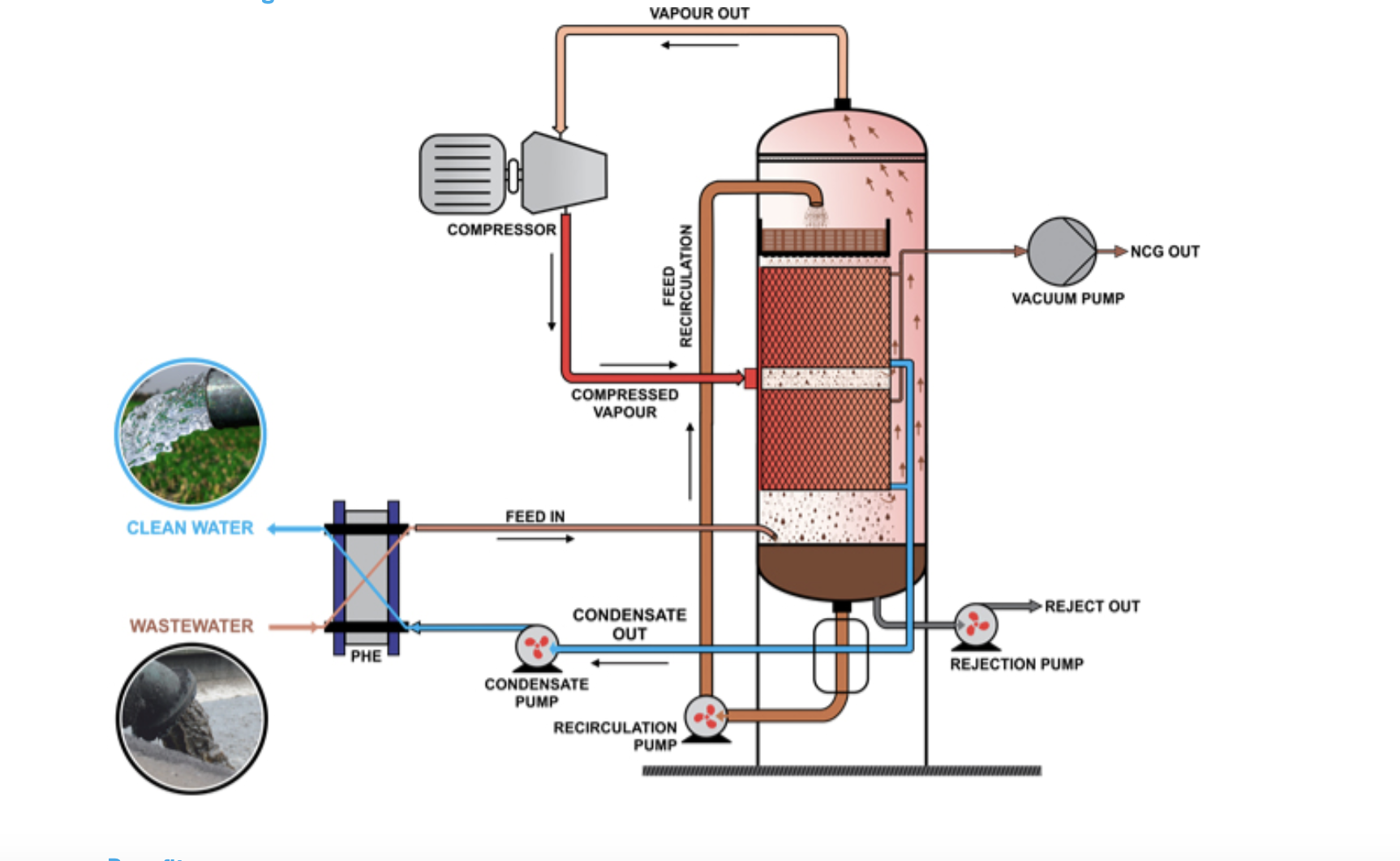

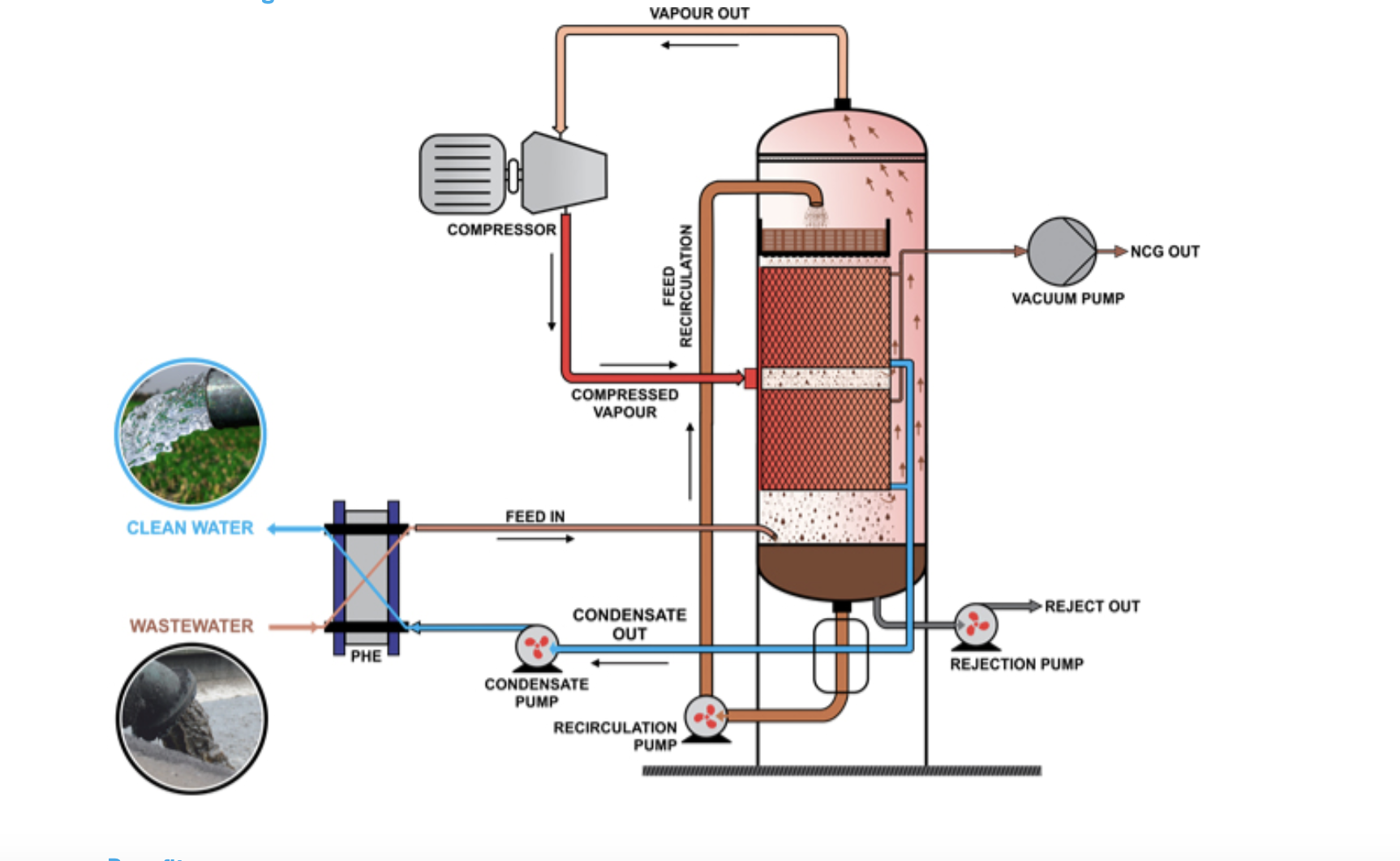

Hero Cycles, a leading name in the bicycle manufacturing industry, has recently integrated the MVR-LTE® (Mechanical Vapor Recompression–Low Temperature Evaporation) technology by Spray Engineering Devices Limited (SED). This advanced process is set to revolutionize water and energy efficiency at their industrial facilities.

What is MVR-LTE® Technology?

MVR-LTE® is a cutting-edge solution developed by SED to optimize energy consumption and improve resource management. The process leverages mechanical vapor recompression to recycle energy, ensuring minimal reliance on external heat sources and operating at low temperatures to preserve material quality.

The applications of Spray Engineering Devices Limited's technologies include the following industries:

- Dyeing Industry

- Distilleries

- Leather/Tannery

- Brine Water Distillation Industry

- Process & Allied Industries

- Pharmaceutical Industry

- Chemical Industry

- Refineries

- Jaggery Plant

- Wastewater Treatment Industry

- Paper & Pulp Industry

- Sugar Industry

- Commercial Buildings

- Housing Colonies

- Dairies

- Hotel & Restaurant

- Textile Industry

- Food and Beverage Industries

Key Benefits at Hero Cycles:

- Enhanced Sustainability:

- Water Recovery:

- Cost Savings:

- High Efficiency in Evaporation Processes:

How Hero Cycles Benefits from SED’s Expertise

- Customized Implementation: SED has tailored the MVR-LTE® process to meet Hero Cycles' specific operational requirements, showcasing its adaptability across industries.

- Commitment to Green Practices: This adoption is a significant step in Hero Cycles’ journey toward achieving greater environmental sustainability and reducing industrial waste.

About Spray Engineering Devices’ Innovation

SED has established itself as a leader in innovative industrial technologies like HEROS (High Efficiency RO System) and MVR-LTE®. These solutions are designed for energy efficiency, water conservation, and cost optimization across industries such as sugar manufacturing, wastewater treatment, and now, bicycle manufacturing.